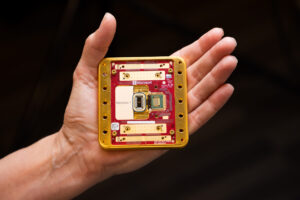

Nanocomp Technologies, Concord, N.H., said it successfully produced a new textile material from long carbon nanotubes, which could be key to key to realizing functional performance benefits in defense and aerospace applications. The material, which uses nonwoven sheet and yarn formats, is extremely lightweight and strong, and efficiently conducts both electricity and heat. “We have a product platform with vast real-world functionality and, together with the system integrators that will ultimately incorporate it into end-use products, we aim to determine just how broad the benefits can extend,” said Peter Antoinette, Nanocomp president and CEO. Carbon nanotubes are 100 times stronger than steel, one-third the weight of aluminum and extremely conductive of both heat and electricity. Antoinette said commercial manufacturing processes to date have mostly produced only short carbon nanotubes — usually tens of microns long — that resemble a powder in final form. These nanotubes can be difficult to incorporate into manufactured goods, and when done so, end products have not yet demonstrated their structural and conductive properties. Nanocomp has overcome these limitations by producing extremely long (hundreds of microns to millimeters) and highly pure nanotubes. These long nanotubes are a key to producing the ultimate functional materials, nanotube yarns and nonwoven sheets, for in end-use applications. Nanocomp said it expects its materials to be used to reduce weight and improve performance of body armor; incorporated into land, air and marine vehicles to improve fuel economy; used for wiring systems and antennas; and to create ultra capacitors to store energy from intermittent energy sources such as wind and solar energy.