Few electronics design areas benefit as much from the use of inductive components as the avionics industry, yet many people feel uncomfortable using these parts, or fail to see their true value. Everyone is familiar with the inductors used in a radio’s tuned RX and TX circuits, but inductive parts have far wider application in modern avionics designs. As more designs need to withstand high transient spikes on DC power and other lines, and more switching DC to DC converters are used, and more sophisticated audio designs become the norm, inductors and transformers are playing an increasingly critical role in successful new avionics systems.

Inductive parts can provide true galvanic isolation, dramatic suppression of high frequency interference, work as energy storage in voltage converters, and provide almost lossless impedance matching and voltage changes. Their ability to provide noise free AC voltage gain without power is an especially useful and unique property. With the recent surge in the popularity of switching converters, many more universal inductive parts have become both inexpensive and readily available to allow their use in all types of power supply circuits. In addition, several manufacturers have also generated a wide range of standardized transformers for audio isolation and impedance matching. Finally, leaded, bead and SMD ferrites have also become common for RF suppression tasks at very low cost. This is a huge change from even 15 years ago, when the choices for these parts were relatively limited, parts were quite bulky, and parts costs were comparatively high.

In addition, many manufacturers now also offer custom parts at reasonable prices, which can make it possible for you to realize very sophisticated designs, especially for audio and DC converter circuits at reasonable prices. This custom capability can be critical for optimizing solutions and solving difficult mechanical packaging problems.

Inside Inductors

Inductance is normally expressed in henrys (H), or some much smaller fraction like millihenries (mH) or microhenries (uH). Of special value to us is the effective AC circuit resistance at some specific frequency, called inductive reactance, expressed in ohms. Inductive reactance is found by the formula XL=2ΠfL. Inductive reactance increases with frequency, while capacitive reactance decreases with frequency. These two factors make a series-shunt LC filter of huge value in suppressing higher frequency noise and interference, while passing DC and lower frequency data. Use of a reactance chart or nomograph makes quick calculations and investigations of suitable values very simple during design.

A simple DC power filter with an inductive series element is increasingly effective with noise frequency, as the inductive reactance rises. The beauty is that the DC resistance or loss remains constant, so our filter woks great at rejecting input noise while adding minimal DC loss to the circuit. This is especially important with input coupled high voltage transients. An inductive series input filter reduces them dramatically, especially when coupled to a shunt transorb device (an equivalent series resistor would be too lossy), making the system much more efficient, robust and resistant to failure. Inductors in the DC power filter, when decoupled on both sides, provide internal noise suppression, and prevent their escape into the external airframe wiring. This is often a critical consideration when using DC to DC converter power supplies.

In addition, substituting a transformer for the inductor in many switchers allows the generation of an additional secondary voltage (set by the turns ratio) of any polarity or left fully floating, which can be of huge value in downstream circuit design. Inductors and common mode chokes (a transformer with identical but out of phase windings) allow effective suppression of noise into your system circuits as well as out into the airframe.

Inductors can be shielded or unshielded, based on their physical construction, and in general terms, it is usually wiser to pick shielded parts in an avionics environment, to control unwanted emissions, especially in switching power supplies. A toroid or closed ferrite design there is often very effective at controlling emissions. All magnetic materials have some temperature dependence, which can dramatically alter performance, especially at the Curie Point or Temperature (Tc), where magnetic field behavior becomes disorganized. Be sure you have investigated any parts to be sure their operating temperature range is suitable for you so you don’t get surprised by this effect at temperature extremes.

Magic of Transformers

How is a transformer useful in the airframe? Aside from obvious applications where it is used to attach to 400Hz AC power busses in larger aircraft, they have huge utility in audio signal processing. Consider an audio amplifier within a radio that has to run from a 9-32VDC input voltage, but needs to generate at least 100-200mW of audio power into a 600 ohm load, while tolerating an output ground, and loading down to 150 ohms. This is an almost impossible problem to solve without a transformer, as a 9V supply can only give about 3.18Vrms or about 17mW into 600 ohms. To get to 200mW, a 31V source (p-p) would be needed, more than a bit awkward at 9V. On the other hand, a low cost IC power amp like an LM386 run from 5-9VDC with an 8 ohm output could easily give the required output simply by adding an 8 to 150 ohm transformer. With enough drive, this also satisfies the 600 ohm voltage requirement, AND works correctly at 150 ohms (providing additional level there), a very common audio driver requirement in aircraft systems. Transformers are of exceptional value in audio output stages.

Good transformer design with a custom part could also provide correctly matched output impedances for 8-20 ohms, 150 or 600 ohms, all from the same circuit, giving a universal headset driver with a very simple design. Need to drive many headsets? Simply modify the windings to give a good match to your combined parallel load, and always use a series resistor with each headset to prevent an accidental short on that line from killing the entire system. The audio driver interface tricks possible with an output transformer and a suitable driver are almost endless. Plus, the huge bonus is that the output is floating, so it can be grounded without harm, but can also be run above ground for minimal ground loop noise interference and resistance to coupled interference.

As an extra bonus, the floating winding is great for resisting coupled transients and RF from the airframe, and serves as a built in low pass filter to help reduce EMI in both directions. It is very hard to make a conventional grounded amplifier pass the entire DO-160E transient abuse profile, but it is dead simple with floating circuits, dramatically reducing certification time and compliance costs as well as over-all system noise rejection.

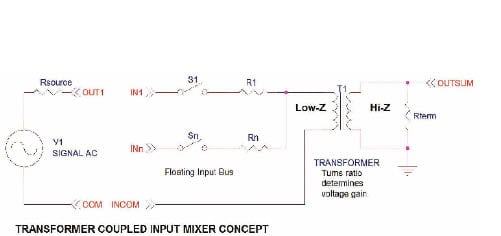

Transformers are also ideal for input isolation of audio signals, and they can be used on a per line basis, or as part of an input passive mixer to give a fully floating audio input system. Mixing sources from a low impedance source via a high value resistor into a low impedance winding is just like mixing with an op amp inverting input. The voltage gain of the transformer restores part of the signal level for post-processing. This technique has been used for decades in systems like the early military C6533, A301 and similar units to dramatically reduce input ground loop noise coupling. Current civil systems like the A710, A711 and A711L are also based on both input and output floating topology, all created with high performance transformers.

Transformers have both turns ratio and winding resistance and impedance values (plus winding inductances as somewhat of secondary characteristic), as well as power handling level and frequency bandwidth, and be aware that impedance is also determined by source and terminating impedances in your circuit, not just the transformer specs. You should also look at more advanced ferrite closed core designs, as they offer a large degree of self-shielding, an important factor for suppressing unwanted emissions, and to shield from unwanted external magnetic fields. Conventional E-I designs can also be shielded with external metal, and toroids are also highly self-shielding, but watch out for any metal screws that pass into the core center, they will act as a winding. Mu-metal or Co-Netic foil can be very useful for protecting and controlling magnetic fields, and is available from Magnetic Shield Corp.

DC resistance values represent copper losses in the transformer, and should be low, frequency, especially the low frequency limit, is usually tied to physical size. It is difficult to get low frequency performance with low distortion from any transformer, but fortunately for us, the audio bandwidth usually does not have to extend below 300Hz, which is helpful in controlling core size. Every part is a blend of various limiting factors, and you should do some experimenting with the parts you intend to use to be sure that frequency response, distortion and heat will all be within the range you require.

Making complex audio designs can be initially breadboarded with stock parts, but then as the strategy crystallizes, the need for modified or custom parts becomes clearer. One of the key players in the custom civil and military avionics magnetics business has become a California company called Magnetic Circuit Elements (MCE). The key difference is MCE is geared to work with comparatively small quantities and highly modified designs needed in the avionics world, and can turn custom parts often in a week for testing. Few other companies will even consider custom parts, and then only in thousands, usually with big NRE amounts attached and horrible delivery, all circumstances not very attractive to most designers. Of particular value is their ability at MCE to make gapped transformers that can work with DC current applied, making many difficult audio interface solutions possible, like mic signal simulators. They are the perfect compliment to the volume magnetic manufacturers for commodity parts like beads and chokes, and allow the designer to fully optimize the final system solution in every way. At the heart of every airborne audio system I have designed for the last 30+ years, there’s usually an MCE part in there somewhere.

The choices for stock pars have improved dramatically, and those working with switchers or needing inductors or common mode chokes can now get a huge array of inductors and switching transformers from Coiltronics (now part of Cooper Bussman, Pulse Electronics, Pico Electronics Inc., Dale/Vishay, Torotel, Toko and Renco.Electronics.

Ferrite parts used to be “magical batwing dust” components, with vague specs and questionable applications, but new material science and aggressive design for EMI suppression has now turned them into very mature parts, with well defined impedances at specific frequencies, and very low cost SMD parts. Key vendors for these are Fair-Rite Products and Laird Technologies, TDK and Murata in Japan, and ABC Taiwan Electronics. Small inexpensive chip parts with specified impedances up to 600 ohms are now quite common, making them very handy in EMI data line and control filter application, and very low loss DC power line decoupling. These ferrites also exist as connector “plates” that slip over connector pins for common parts like D-sub connectors to aid in filtering all lines. Keep in mind, to be truly effective, these should terminate in a shunt capacitor, or their effect will be low unless your lines have very low impedance to start with. They have also become very popular as HF noise rejection filters in digital circuits (coupled with a shunt capacitor), when used to isolate and decouple DC power to noisy digital subsystems. Their very low insertion resistance but high impedance at frequency makes them ideal in that application.

Ferrites differ from a regular choke in that they are not specified in terms of inductance, but rather in terms of some repeatable impedance at a known frequency. In addition, some can be placed over wires without any electrical connection (they are actually working as a half-turn of a toroid), and still work, which many find utterly baffling. This has given them a somewhat spooky flavor to many designers, but the underlying science is actually pretty clear, and highly useful in quenching unwanted ringing, RFI emissions or susceptibility.

Stock miniature audio transformers with high performance suitable for avionics work are available from Triad Magnetics (SP-series and MET-T series), Tamura Corp. (MET-series), Pico Electronics, and Hammond Manufacturing (101-109 series). Interestingly, Triad now also supplies the MET series, and still offers a compatible magnetic shield, which Tamura thoughtlessly discontinued. These MET style transformers are great parts, and I have used them for decades to solve all kinds of tricky low-level audio interfacing problems where space was a problem.

Avionics designers now have a huge range of inductive parts and transformers to select from, as well as a way to get small quantity custom designs within their budget. This now allows a much more elegant design solution with better capability than ever before. If you have shied away from these parts in the past, now is a good time to investigate what they can do for you, and add them to your design toolbox. Many vendors now offer sample boxes to help you evaluate parts, or on-line sample ordering, which makes exploration of these parts much simpler in many larger organizations where procurement is complicated.

So, no more excuses, explore what these inductive components can do for your design.

Walter Shawlee 2 is the president of Sphere Research Corp. in West Kelowna, British Columbia, Canada, and a senior designer at Technisonic Industries. He can be reached at [email protected].

To see a complete archive of Shawlee’s System Design columns, visit www.aviationtoday.com/shawlee.