Airbus E-Fan X First Flight to Occur in 2020

By Woodrow Bellamy III | November 28, 2017

Send Feedback | @WBellamyIIIAC

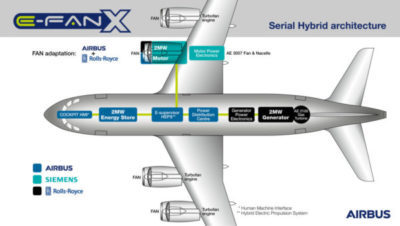

The E-Fan X. Image courtesy of Airbus.

Airbus, Rolls-Royce and Siemens are targeting 2020 for the first flight of the E-Fan X. The companies see the first flight of this “near-term demonstrator” as a major step toward achieving Airbus CTO Paul Eremenko’s goal of introducing electric hybrid propulsion technology into future passenger airframe designs.

The three-way partnership was announced during a press conference Tuesday at the Royal Aeronautical Society in London. Airbus and Siemens have conducted several small-scale electric propulsion demonstrator aircraft flights since 2013, and both companies have been researching a full-scale concept at their E-Aircraft Systems House near Munich, Germany.

A graphic of the future airframe provided by Airbus shows that the E-Fan X will feature three turbofan engines and a two-megawatt electric motor, along with a power distribution center and “E-Supervisor” hybrid electric propulsion system. According to Siemens, the electric propulsion system obtains its power from a generator that is powered by a turbine in the fuselage. E-Fan X will also feature lithium-ion batteries with 700 kilowatts of power.

The three companies are using a BAE 146 regional aircraft as the flying testbed for the demonstrator flight, which was selected because it features four engines, said Paul Stein, CTO for Rolls-Royce. One of the 146’s engines will be replaced by the electric motor.

Under the partnership, Siemens is providing the motor and power distribution system, while Rolls-Royce will supply the turboshaft engine, two-megawatt generator and power electronics. Airbus is providing the overall integration of the hybrid-electric propulsion system and batteries control architecture and integration with aircraft flight controls.

Eremenko, who was appointed CTO of Airbus last year, ultimately wants to develop a hybrid electric propulsion architecture capable of supporting a single-aisle aircraft the size of an Airbus A320, which would require 20 megawatts of power for cruise. One of the biggest obstacles that the three companies will have to overcome is the reality that today a hybrid power chain is less efficient than a conventional gas turbine engine because of the need to convert conventional gas to and from electrical energy.

“The lessons we learned from a long history of electric flight demonstrators, starting with the Cri-Cri, including the e-Genius, E-Star and culminating most recently with the E-Fan 1.2, as well as the fruits of the E-Aircraft Systems House collaboration with Siemens, will pave the way to a hybrid single-aisle commercial aircraft that is safe, efficient and cost-effective,” said Eremenko.

Eremenko spoke at length during the 2017 American Institute of Aeronautics and Astronautics (AIAA) Aviation Forum about how he believes hybrid electric propulsion will become commercial aviation’s next landmark achievement in the future.

Airbus also believes that electric hybrid propulsion technology could help the aviation industry achieve the European Commission’s goal of reducing carbon dioxide emissions generated by commercial aircraft by 75% by 2050.