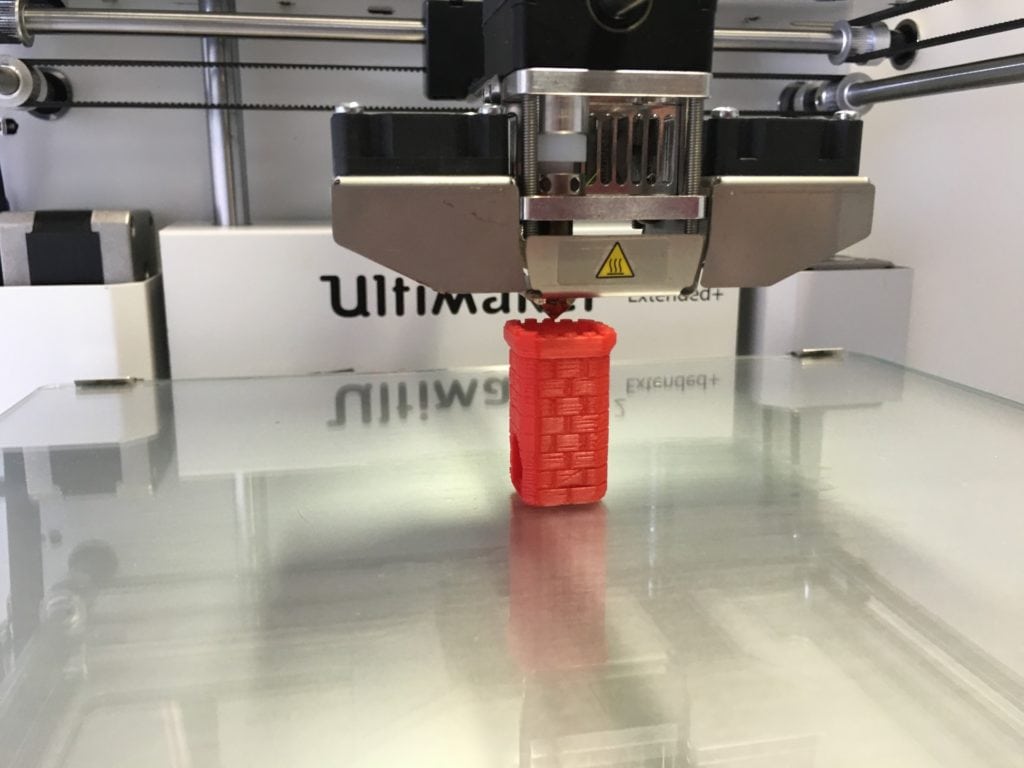

Large-scale 3D Printing could account for more aerospace manufacturing in the future. (Free use photo under Creative Commons)

Boeing says it has around 50,000 parts flying today that were created via 3-D printing. Through a five-year pact with Swiss technology group Oerlikon, it hopes to increase that number.

3-D printing, also called additive manufacturing, uses a laser to melt material in successive layers to build something according to a computer-generated blueprint. In the case of aerospace applications, the material being melted is likely a titanium powder.

According to Boeing Chief Technologist Leo Christodoulou, the two companies will “work together to standardize additive manufacturing operations” in the pursuit of an efficient and reliable process.

Boeing hopes to get to the point that it can have a large-scale supply chain for 3-D-printed aerospace parts that meet quality and cost targets, and the partnership with Oerlikon, which has ample experience on that front, is intended to help it get to that point.