Honeywell Forge for Airlines analytics platform. Photo: Honeywell Aerospace

A new unified analytics-based software platform, Forge for Airlines, was able to reduce delays and cancellations by 30 percent for Cathay Pacific, according to Honeywell Aerospace. Could it be the centralized access point to actionable aircraft data analysis that airlines have been craving?

First launched in June, Honeywell Forge is a new data analytics technology stack capable of collecting, cleaning and analyzing wide swaths of data from a variety of airline sources for predictive analytics. The tool can provide an accurate forecasting of how much money an airline such as Cathay can save based on the type of data-driven decision-making that they’re engaged in.

“Today the traditional workflow is that a data analyst for the airline would have to go out to the IT department and have them run a ticket, said John Peterson, vice president and general manager of software and services at Honeywell Connected Enterprise. “The ticket would pull all of this data and then they’d have to sit down and sort it out in spread sheets and then they’d have to figure out how to draw conclusions from it. Then from those conclusions, the analyst figures out the initiatives that they can do, and then they repeat the process again.”

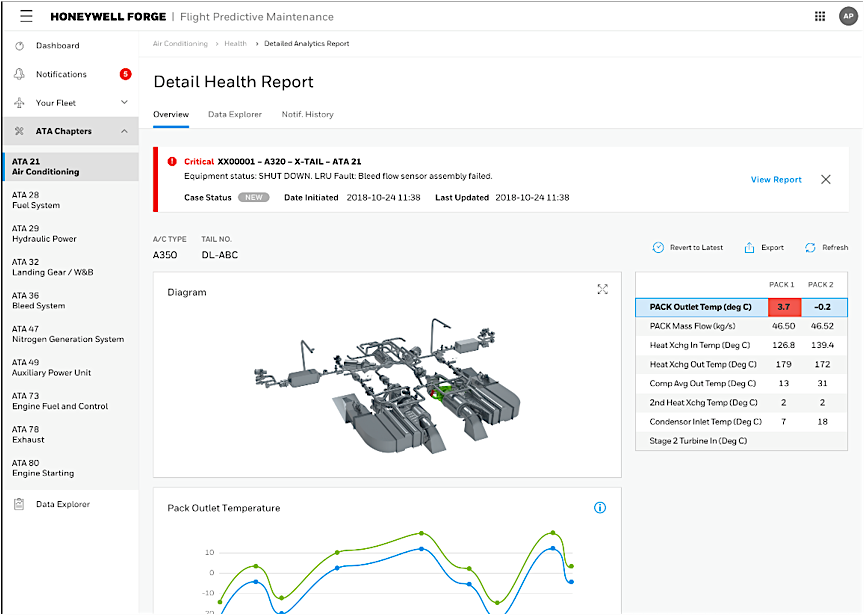

One of the dashboards provided by Honeywell Forge. Photo: Honeywell Aerospace

Peterson said the Honeywell Forge analytics platform automates that entire workflow by using a combination of edge processing and data acquisition on aircraft system and components along with algorithms and data analysis on the ground. Once data is captured and analyzed, Honeywell presents it to the relevant airline personnel in an easy-to-understand dashboard format.

Forge is capable of providing predictive maintenance alerts and can be interfaced in a customizable way to send and receive data to airline specific application programmable interfaces, algorithms and other processes, according to Peterson. Across 61 aircraft operated by Cathay Pacific, Forge captured 44,000 fault messages and a total of 1.6 million flight records to produce a predictive model report for the airline’s maintenance team up to three days before some components on those aircraft were projected to fail.

The new platform is one of the latest aircraft data analytics technologies to be introduced in recent years, as airlines are also using other new solutions including Airbus’ Skywise, Teledyne’s AirFASE and even Google’s BigQuery. The new platforms are an extension of newer quick access recorder and aircraft data integration technologies that are increasingly becoming standard on aircraft.

As an example, the Airbus A350 and A320neo now feature an onboard flight operations and maintenance exchanger (FOMAX), a secure server router and compact connectivity unit that gathers aircraft maintenance and performance data and automatically sends it to maintenance control center engineers and technicians. Avionica and GE Aviation have taken a similar approach, leveraging Avionica’s quick access recorder technology and GE’s advanced data analytics platform to provide integrated solutions to operators.

Now, with Forge, Honeywell can pair its own advanced data analytics platform with its aircraft data gateway box, first introduced in 2017, as method for wirelessly transferring data on and off of aircraft, though Peterson said Forge works with any available quick access recorder or edge processing onboard system.

“The way it actually works is we collect the data at a frequency rate that is determined by the airline. Then we have trending and monitoring occurring in the background. So we’re constantly processing as the data is being collected, then what ends up happening is we provide alerts that say ‘we see an event here that needs to be addressed.’”

Peterson said Honeywell now has more than 100 airlines and 8,000 total business and commercial aircraft utilizing Forge.