A special committee established by U.S. Department of Transportation Secretary Elaine Chao, released its report on the 737 MAX certification process after more than six months of study and evaluation. Photo: Department of Transportation

A new 68-page report published by the independent special committee tasked with reviewing the certification process followed by the FAA and Boeing for the 737 MAX found a major need for workforce modernization and improvements in the way the FAA handles delegation and accounts for innovation introduced into new commercial airplane product designs.

The report is the result of a six-month study and evaluation of the certification process applied to the Boeing 737 MAX 8 program between 2012 and 2017. A set of 10 different recommendations were provided by the committee, including a requirement for design and manufacturing organizations to implement safety management system (SMS) programs, aggressively developing the FAA’s workforce to meed evolving industry needs, and a clarification of the FAA’s policy for amending product type certificates.

The committee was co-chaired by Captain Lee Moak, a former U.S. Marines Corps and Delta Air Lines pilot who retired from his position as president of the Air Line Pilots Association (ALPA) in 2014, and retired U.S. Air Force General Darren McDew, who retired from his position as command of the U.S. Transportation Command post in 2018. Their report stressed their task and goal of reviewing the certification process itself, rather than conducting a technical evaluation of the performance of the MAX itself.

Among the various recommendations, which the committee also described in a 12-page executive summary of the report, several key findings were repeatedly mentioned, including a need for the FAA to establish an aggressive recruitment campaign designed to identify skills, provide skills development programs and attract talent that is able to evaluate the safety and airworthiness of new and novel technologies being integrated into modern technologically advanced airplanes.

Recommendations aimed at improving the FAA’s organization design authorization delegation process for conducting aircraft certification was one of the workforce modernization efforts that the agency needs to undergo, the report said. According to the committee, personnel with more knowledge of “systems thinking” should be given oversight responsibility for overseeing the design authorization processes managed by organizations such as Boeing. The committee also identified skill gaps needed to be addressed by the FAA’s Aircraft Certification Service (AIR).

“As AIR continues its transformation, it is likely the FAA will require personnel with different skill sets. Backgrounds in data analytics, systems engineering, operations research, and program management are critical additions to technical disciplines when seeking to follow a harmonized multidisciplinary approach,” the report says.

Reviewing the ODA process itself also led to the committee’s recommendation for the agency to address concerns about “potential undue pressure” that may be placed on individuals involved in the process that could keep them from acting independently of the organizations’ application for achieving a new or amended type certification.

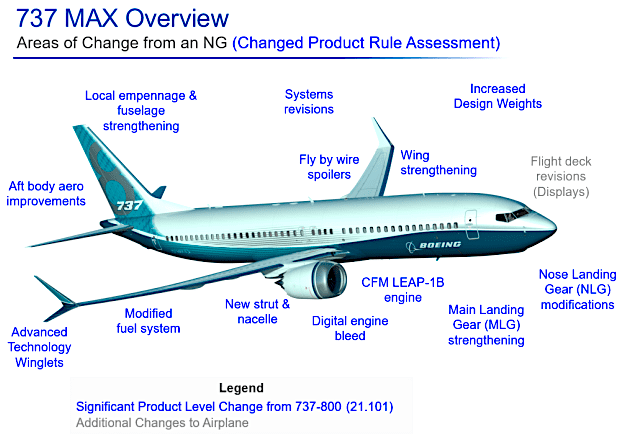

As the biggest change to the flight control system on amending the type certificate from the 737 NG to the 737 MAX, the special committee found that the FAA retained design approval for the Maneuvering Characteristics Augmentation System (MCAS) and only delegated certification of the system to Boeing’s ODA after “several years of design review and discussion.” MCAS was identified and tested during both Boeing and FAA certification flight tests, however the agency’s protocols did not require testing of MCAS for combinations of mechanical and human failures.

“Boeing and FAA inspectors determined that a malfunctioning MCAS system would present itself as runaway stabilizer trim, an occurrence with specific non-normal checklist procedures and for which pilots are trained to address,” the report says.

The committee further described MCAS as an extension of the previous generation 737-800’s speed trim system, which had already exhibited more than 200 million flight hours of operational safety by the time certification process for the 737 MAX program began. Malfunctioning of the MCAS system in both the Ethiopian Airlines and Lion Air crashes has been the focus of the investigation into the cause of both accidents. The final accident report on the Lion Air crash noted that a breakdown in safety oversight of certification and design flaws shared between Boeing and the FAA for reviewing MCAS was among several factors that caused flight JT610 to crash.

Another major recommendation made by the special committee is for the FAA to start requiring design and manufacturing organizations to implement the same SMS requirement that was adopted as a mandate for part 12 air carriers by the FAA’s Aviation Safety Organization in 2015. An SMS is described by the committee as “a formalized, safety risk-based approach to the management of an organization, whereby every process, decision, activity, acquisition, procedural change, or program modification is examined from a holistic safety risk perspective in order to ensure that all of the potential associated hazards are uncovered, examined, and mitigated.”

Boeing has taken a number of steps toward its goal of returning the grounded MAX fleet to passenger carrying service. Production of the MAX has temporarily been halted, so the company can focus its complete attention on producing a software update and addressing design changes necessary to meet the satisfaction of the FAA and other civil aviation regulatory agencies. Since the grounding of the MAX fleet, which has now reached 10 months, Boeing has produced a total of 400 MAX aircraft that are currently awaiting deliveries to customers.

David Calhoun officially took over as the new CEO of Boeing on Jan. 13. In a press release published several days before Calhoun took over, Spirit AeroSystems – Boeing’s biggest supplier and manufacturer of the MAX fuselage – announced it would be furloughing approximately 2,800 workers due to uncertainty related to the timing for resuming MAX production.

None of the civil aviation regulatory agencies, including the FAA, have indicated or set a timeline as to when they expect the aircraft to be ready to return to passenger-carrying service.