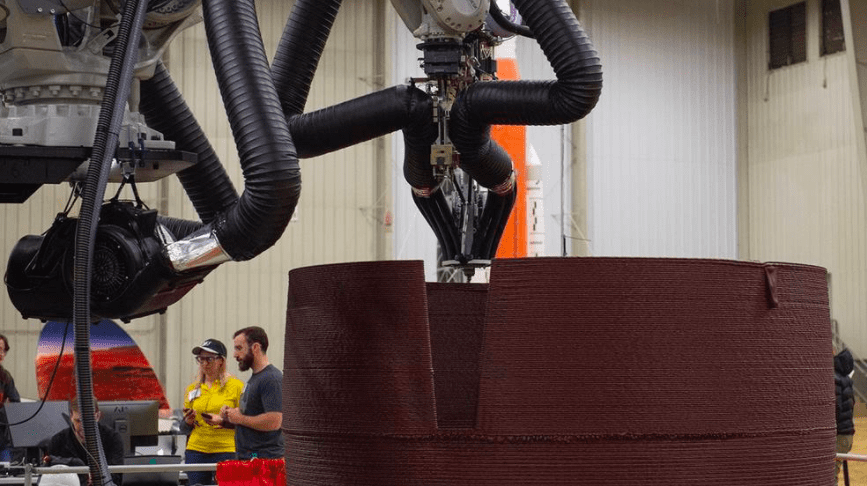

During the final, demonstration level of NASA’s 3D Printed Habitat Challenge, AI SpaceFactory autonomously printed a habitat and tested technology for building structures on the Moon and Mars (NASA/Emmett Given)

The National Aeronautics and Space Administration (NASA) made an Announcement of Collaboration Opportunity (ACO) with 17 U.S. companies for 20 partnerships to mature space technology. The ACO, which is unfunded, will last between 12 and 24 months and has a total estimated value of $15.5 million, according to a NASA press release.

The industry teams selected for the ACO will work on projects to mature a first-stage rocket recovery system for a small satellite launch provider, test a method for removing dust from planetary solar arrays, and design a 3D printing system for NASA’s Artemis lunar exploration program among other projects. The teams will also be working with technologies like cryogenic fluid management and propulsion, sustainable power, and small spacecraft technologies.

While the program is not funded, companies will have access to NASA’s testing facilities.

“Space technology development doesn’t happen in a vacuum,” Jim Reuter, the associate administrator for NASA’s Space Technology Mission Directorate (STMD), which made the selections and will manage the partnerships, said in a press statement. “Whether companies are pursuing space ventures of their own or maturing cutting-edge systems to one day offer a new service to NASA, the agency is dedicated to helping bring new capabilities to market for our mutual benefit.”

Northrop Grumman Space Systems Orbital Science Corporation will be developing an electric propulsion system for the ACO. They will be working to advance a low power high throughput Hall thruster system for small spacecraft, Joe Anderson, senior director of on-orbit service assembly and manufacturing at Northrop, told Aviation Today.

“We’ll be looking to test the life cycle and wear testing on a thruster itself, so we Northrop Grumman, will be building a H71M engineering model thruster to NASA’s design, and then NASA will conduct lifecycle testing and wear testing on that thruster, and then after that perform some integrated system testing, together with the TPU and the Xenon flow controller,” Anderson said.

Anderson said that this project will expand the possibilities for NASA’s science missions by allowing them to complete projects at a much lower cost.

Sensuron is working to develop a miniature rugged temperature monitoring solution using a fiber optic sensing system under the ACO. Justin Braun, president of Sensuron, told Aviation Today that their goal is to provide more accurate and reliable measurements for cryogenic fuel tanks.

“One of the interesting portions about Sensuron and the baseline technology, the continuous fiber optic sensing, is that we actually started off by licensing the baseline technology from NASA, from our parent company, back around, I think, 2010,” Braun said.

While Braun said most of the instruments Sensuron makes are sold into aerospace, the ACO could allow them to expand into different environments like space and underwater. “I think there’s a lot of technologies that are born out of NASA and the interesting thing here is that we were able to make commercial offerings and base a company off of that foundational technology,” he said.

Ahmic Aerospace will be developing thermal protection systems to protect rockets and spacecraft from extreme heat for the ACO. To do this, they will be measuring the wall shear skin friction on thermal protection systems, something that historically has not been done, Ryan J. Meritt, president of Ahmic Aerospace, told Aviation Today.

“Our question, what are we trying to redress, is as the material shed, as the material becomes more pockmarked and rough and the properties essentially are changing, what does that do to vehicle performance,” Meritt said. “Surface roughness is going to go up, with that comes more wall shear with more wall shear comes more friction, and with more friction comes more heating, and then the process gets even worse. So, how long can that continue on for?… So now, how do you control a vehicle that changes over time? And then again, if we can kind of understand these performance maps of the TPS system over time, that allows you to kind of ultimately, I think what this boils back to is being able to predict this.”

The ACO will also work to develop a non-toxic propellant with higher performance and density but lower volume than the commonly used hydrazine. Aerojet Rocketdyne will be working on this project with its new hybrid propellant of green ionic liquid. Joe Cassady, executive director for space at Aerojet Rocketdyne, told Aviation Today that the propellant is a new blend of water and the same chemicals used in hydrazine.

“It is just basically that, it’s watering it down and then, by doing that, our goal is to two things: we want it to be non-toxic but also as we started developing this we realized that we can actually get higher performance, and especially for the small satellite, the density that we can store that is better,” Cassady said. “So for the same volume on a spacecraft, we have a small tank that on one of these cube SATs you don’t have a whole lot of room to store propellant because you have to leave room for all the good payload stuff that you guys started developing in the avionics industry.”

Other companies selected for the ACO include AI SpaceFactory, Blue Origin, Box Elder Innovations, Cornerstone Research Group, Elementum 3D, Gloyer-Taylor Laboratories, IN Space, pH Matter, Phase Four, Rocket Lab USA, SpaceX, Space System Loral, and Stellar Exploration Inc.

The ACO along with NASA’s 2020 Tipping Point partnerships supports technology development which will lead to a sustainable presence on the Moon and future crewed missions to Mars, according to NASA.