Honeywell and DENSO Corporation are working together to develop an electric motor for Lilium’s vertical take-off and landing aircraft. This collaboration is a continuation of a 10-year-long alliance agreement signed last year to design and develop electric propulsion systems, as well as joint research that started in 2019. Honeywell has also been working with Lilium for nearly two years to create a solution for the Lilium Jet.

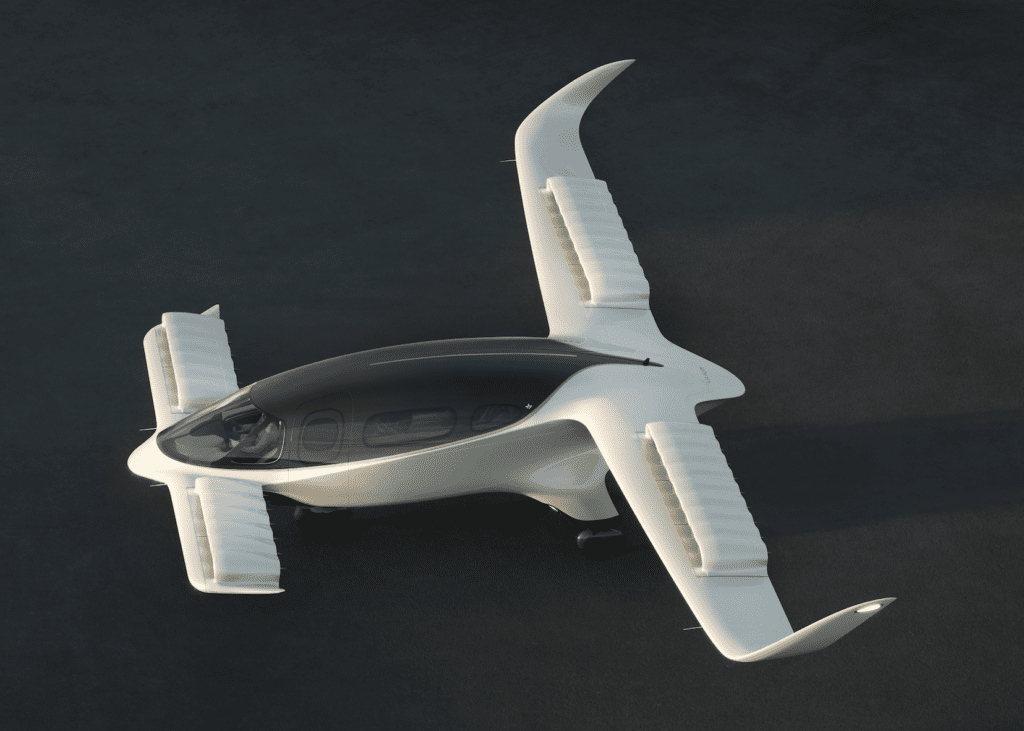

Pictured above is the Lilium Jet eVTOL aircraft. “It’s really about creating Aerospace 2.0, or Aviation 2.0,” said Taylor Alberstadt, Honeywell’s Global Sales and Marketing Lead of the UAS/UAM group, discussing the alliance with DENSO to create an e-motor. “A new way to move people or cargo. And the heart of that is doing it in a more sustainable way.”

Taylor Alberstadt, Global Sales and Marketing Lead of Honeywell’s UAS/UAM group, noted that this is a 50/50 partnership with automotive components manufacturer DENSO. “It is truly a coming together of two equal industry giants,” he told Avionics International in an interview.

The e-motor is designed with Lilium’s unique needs in mind, and it weighs less than 4 kilograms while providing 100 kilowatts of electric power. As far as their timeline for development, Alberstadt says, “We are in lockstep with Lilium’s program milestones, and as they talk about the evolution of their program and entry into service, the development and work that we’re doing for the Lilium Jet is in line with their schedule.”

Pictured above is a prototype of the rotor.

Stator prototype. (Photos courtesy of DENSO)

A key part of Honeywell’s mission is to help their OEM partners come to market—and in some cases to create the market. The Honeywell team works to provide content across a vehicle, “whether that’s avionics with our new Anthem cockpit, actuation, flight controls, electric propulsion, power distribution, turbomachinery, or hybrid-electric vehicles,” said Alberstadt. It is not simply integration of avionics products or propulsion systems that provides value; it’s integration of the entire vehicle.

The UAM/UAS group at Honeywell was established several years ago to enable consolidation and alignment of Honeywell Aerospace’s products for the advanced air mobility (AAM) industry. This organizational change illuminated necessary changes to Honeywell’s existing product line, explained Alberstadt, and also revealed opportunities for creating entirely new products. One example is the compact IntuVue RDR-84K radar system, designed specifically for the AAM market. He noted that the exclusive focus on AAM “gives us the ability to be more nimble, to act like a startup, and leverage the legacy, the process, the heritage, and the funding.”

DENSO has an extensive history in electrification, and has also demonstrated high levels of automation in mass production, Alberstadt observed. Honeywell brings expertise in certification and certified software development along with its legacy in aerospace and relationships with many players in the AAM market.

Honeywell’s decision to collaborate with DENSO was informed by the realization that the AAM industry would not look exactly like either traditional aerospace or the automotive space but an overlap of the two areas. “We thought about the Honeywell portfolio and how we wanted to be a major player across the entire vehicle,” remarked Alberstadt. “We recognized that from an electric propulsion point of view, there were areas where we could complement our existing technology with that of a partner.”

The production volumes that will be required for the emerging AAM industry “are not reflective of what aerospace is typically comfortable producing,” Alberstadt explained. DENSO’s capacity for automating mass production of high-quality products—for example, production lines that make upwards of 20,000 products a month—made it Honeywell’s number one choice for this collaboration.

In the next six to eight weeks, Honeywell expects to report on the progress and updates from a program in collaboration with DENSO that started in April 2021. The two companies have developed an understanding of the diversity of designs for AAM vehicles in order to identify a core set of requirements, which will inform the design of an electric propulsion system. They expect the end result to be a product that can be integrated into several vehicles, according to Alberstadt.