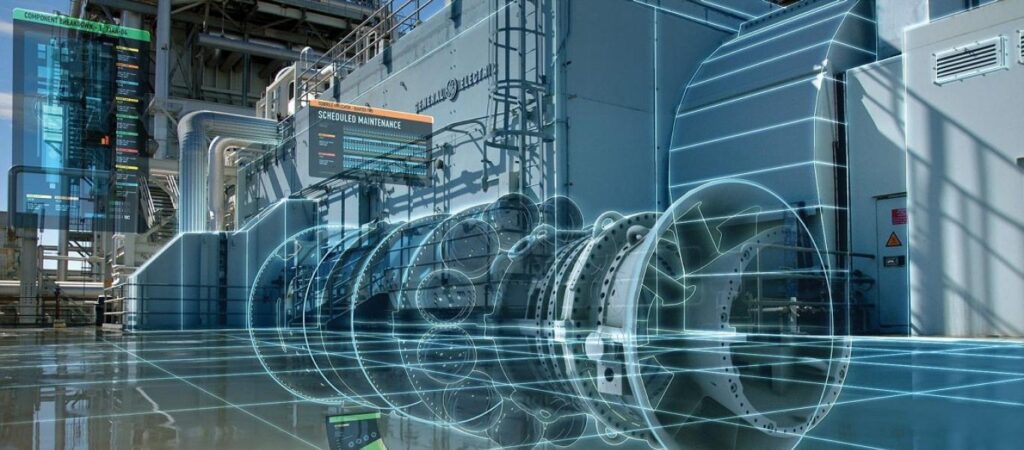

Aerospace and defense (A&D) investment in digital twin technology has grown by 40% over the last financial year. (Photo: GE)

The aerospace and defense industry is constantly investing in new designs and concepts to improve aircraft efficiency and capabilities and support technological infrastructure. Despite its consistent innovation, this sector is notorious for being responsible for large amounts of carbon emissions in the atmosphere, making the testing and introduction of cleaner technology important to both the industry and the world. A new study from Capgemini has shown that aerospace and defense firms have continued investing in digital twin technologies to help create modern solutions in a greener and more sustainable manner.

Digital twins are digital replicas of physical assets, systems, or processes. Existing only in a virtual setting, digital twins make it possible to test a variety of questions and innovations cost-effectively, as the process does not require undergoing the costly and timely process of developing a physical prototype or simulating physical conditions in an authentic setting. This technology allows for major design questions to be answered and decisions to be finalized prior to the production of a physical prototype- helping lower costs and in many cases the time to market.

This technology could be beneficial to the aerospace and defense industry. The sector is currently facing many daunting challenges, including a skilled labor shortage and an aging workforce that has resulted in firms struggling to maintain the human capital they need. Furthermore, supply chain disruptions have led to increased difficulty for firms as they design new concepts and prototypes. However, perhaps the biggest issue digital twin technology will address is carbon emissions. After all, the aviation industry alone was responsible for emitting over one billion tons of carbon dioxide in 2018. As a notorious contributor to climate change, the industry’s use of this technology will allow it to design more environmentally-friendly concepts at a fraction of the cost, fostering innovation and a movement toward sustainable technology.

The goal to decarbonize aviation is widely recognized as one of importance for the industry, and 67% of companies claimed that decarbonizing the industry was driving investments in digital twin technology. This figure is up from 60% in 2022. As an alternative to burning fossil fuels, firms have been heavily investing in new technologies like electric batteries and hydrogen fuel to power flight- and 75% said that digital twin technology immediately added value to product/system development. This is mainly because it allows engineers to validate steps of the design process virtually, thus reducing testing time for prototypes.

(Photo: Capgemini)

As Capgemini’s study highlights, some of the biggest companies in the sector have begun to acknowledge the advancements digital twin technology will help them make. Max Egorov Nova, Airbus UTM’s Head of Simulation, explained, “Our digital twin allows us to model, simulate, and scale a wide range of situations for critical stakeholders, including drone and aircraft pilots, operators, regulators, and the UTM [uncrewed traffic management] service providers themselves.”

While almost half (47%) of the firms surveyed as a part of the study believed that utilizing digital twin technology in the design phase of new products will help companies yield short-term benefits, its usefulness can extend beyond design. Many believe that developing virtual network environments, in which companies can simulate and analyze the flow of products through a supply chain, can help optimize current systems and proactively counter future challenges. 39% of surveyed firms believe that this technology can help optimize supply chains, and 81% agree that digital twins help improve the reliability of their systems.

As recovery from the pandemic continues, businesses across the aviation industry are “beginning to appreciate that digital twins hold greater value than just creating 3D models of products and solutions. Digital twins’ true potential is being able to accurately simulate every step of the creation process from design, manufacturing, and through real-world operations and applications,” explained Lee Annecchino, Global Industry Lead for Aerospace and Defense at Capgemini. “If greater investment in the technology continues, as our research indicates, digital twins will enable automation at every point on the value chain, generating significant cost reductions and driving innovation.

As the aerospace industry continues to pursue new, climate-friendly technologies to make air transport more sustainable, digital twin technology has shown to be capable of reducing costs of development and giving engineers a better understanding of how new technology will operate and impact the external environment. Investment and use of digital twin technology are likely to continue growing as more firms turn to it as a viable solution to their design needs.