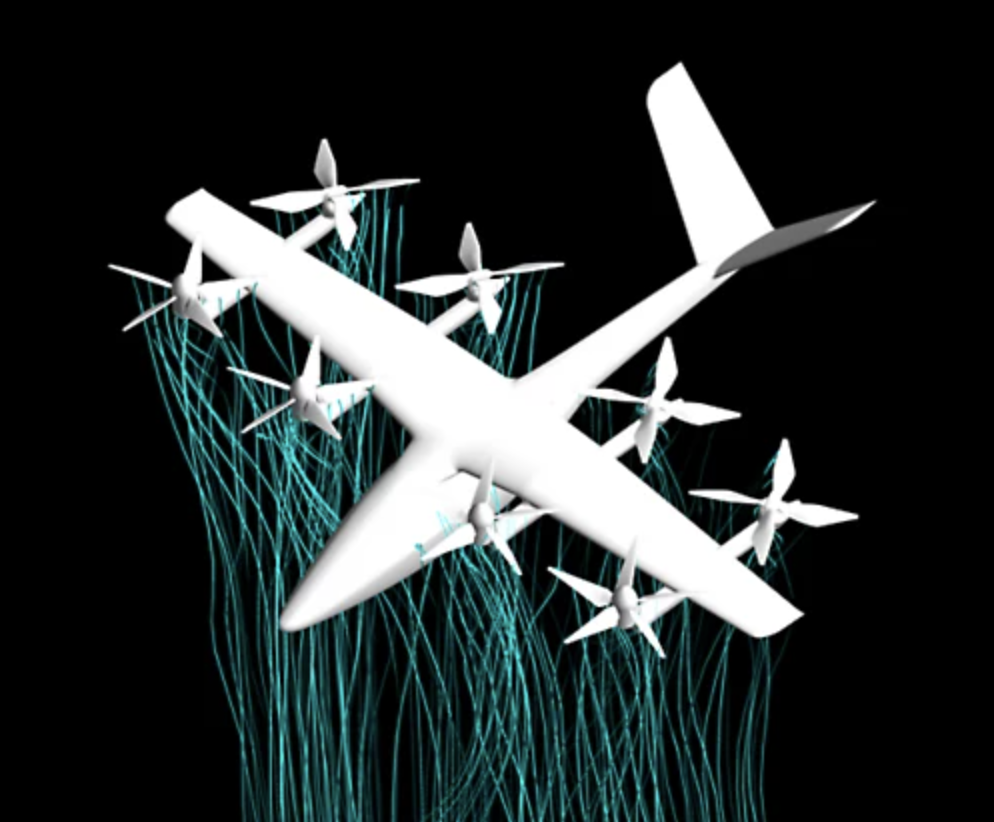

The aerospace sector is increasingly setting its sights on automation, simulation, and sustainability. (Photo: Vertical Aerospace/Ansys)

The International Air Transport Association (IATA) has published multiple roadmaps outlining how the industry can achieve net zero carbon emissions by 2050. One roadmap details the development of more efficient aircraft that operate using sustainable aviation fuel, hydrogen, or batteries. IATA also recommends strategies for reducing the emissions of existing aircraft. Aviation companies now have to balance expensive and time-intensive development of new flight technologies in addition to maintaining operations with record air travel demand.

The aviation industry has been pivoting for some time now in the direction of sustainability. In a recent discussion with Dr. Pepi Maksimovic, the Director of Application Engineering at Ansys—a prominent player in the field of engineering simulation—Avionics International examined the current trajectory of the aviation sector and its aspirations towards a more eco-friendly future.

(Photo: IATA)

Climate change remains one of the most pressing global concerns today. Rising temperatures, coupled with escalating greenhouse gas emissions, have brought the issue of sustainability to the forefront. Corporations, nations, and individuals are becoming acutely aware of their environmental impact and are seeking ways to minimize their carbon footprints. “Everybody’s looking at what their responsibility and contribution is, and what can be done,” Dr. Maksimovic said.

She pointed out the radical transformation in the business landscape over recent years. More than ever before, sustainability is not just an afterthought; it’s reshaping corporate strategies and outlooks. A notable surge in companies aligning with green initiatives and setting environmental targets is evident.

(Photo: Farnborough International Airshow)

When narrowing the focus to aviation, two principal areas come under scrutiny: propulsion technology and fuel. While improving engine efficiency is vital, the search for sustainable alternatives to traditional fuels is equally imperative. This is where sustainable aviation fuels (SAFs) come in. These fuels, which can currently be blended up to 50% with conventional jet fuel, have the potential to significantly cut emissions. However, Dr. Maksimovic noted, “Because they’re produced in smaller quantities, they’re more expensive than conventional jet fuel.”

“The chemical properties of SAFs are different, so they don’t interact with seals and other sealing components in the same way,” she explained. “There’s a potential of fuel leaking.” The engineering challenge is modifying propulsion systems to accommodate a higher percentage of SAFs, bringing it closer to a 100% blend.

It’s not just about finding alternative fuels. Dr. Maksimovic emphasized the significant strides being made in aircraft electrification, highlighting the exploration of hybrid technologies. Beyond this, the promise of hydrogen looms large. Its potential as a carbon-free fuel source could be revolutionary for the sector.

Aircraft design, particularly concerning fuselage shape and aerodynamics, also plays a significant role in improving fuel efficiency. As propulsion systems evolve, so too does the aircraft’s overall structure. This dynamic interplay between engine and design necessitates ongoing refinements in integration.

(Photo: Farnborough International Airshow)

Additionally, advancements in materials science are crucial to sustaining these engineering innovations. The push towards higher operational temperatures requires the development of materials that can withstand such extremes. “Looking at advanced materials that can sustain and operate in these elevated temperatures, like advanced composites,” is an active area of research, Dr. Maksimovic noted.

The product portfolio offered by Ansys boasts a robust array of software solutions, all rooted in modeling the physical realities defined by equations that describe our world. This physics-based approach ensures accurate simulation results in a multitude of fields, from fluid dynamics and structural mechanics to electromagnetics and semiconductor processing.

How does this simulation technology lend itself to sustainability in aviation? Firstly, by transitioning to computer-based modeling, the need for numerous physical prototypes diminishes. This not only accelerates the development process but also conserves vital resources, ensuring minimal waste.

“Our software is being used every day by engineers, designers, and scientists to help them innovate, create devices, sensors, hardware, et cetera, to make those products better, or to come up with something brand new and innovative,” Dr. Maksimovic shared.

She underscored the vast design space exploration that virtual simulation affords. By enabling engineers to fine-tune designs virtually, companies can ensure that products perform optimally in real-world scenarios. This approach becomes pivotal when considering the urgency of reaching sustainability targets set for the coming decades. Technological innovations, both incremental improvements to existing solutions and the development of groundbreaking new technologies, are essential in meeting these goals.

However, she also highlights a critical aspect of this transition—the timely and cost-effective deployment of these technologies. Accessibility is just as important as innovation. For technology to have a significant impact, it must be affordable and scalable, ensuring widespread adoption. Achieving net-zero targets will necessitate a colossal shift in technology consumption, a shift that will demand not just a few, but millions of devices and systems in operation. In essence, to revolutionize the aviation sector, sustainability-driven technological advancements need to be democratized, ensuring they reach the masses and are produced at the scale required to truly make a difference.

(Photo: Ansys)

The aerospace sector is increasingly setting its sights on automation and autonomy, a trend Dr. Maksimovic and the team at ANSYS are keenly focused on. Autonomy spans various terrains including air, space, and land, for both defense and commercial applications. With the increasing interconnectivity and communication capabilities of autonomous vehicles and components, the need for intricate and intelligent technologies is paramount. These smart technologies, communicating seamlessly with each other and their controls, represent a leap in aerospace efficiency and effectiveness.

The reach of automation extends beyond just the end products. The internal workflows, particularly those rooted in simulation, are also seeing significant advancements in automation. Traditionally, engineers would manually interact with software, inputting data, analyzing results, and making modifications. However, with the automation initiatives spearheaded by ANSYS and its ilk, much of this process can be streamlined. For instance, with the push of a button, engineers can initiate a series of automated simulations, allowing the system to analyze numerous scenarios and then present the most optimal outcomes.

“The machine analyzes a bunch of scenarios in the background, extracts results, and presents it to the engineer or designer, who can then use their know-how to figure out what makes sense,” according to Dr. Maksimovic.

She added that the broader impact of this evolution is that engineering teams can pinpoint superior design solutions at an accelerated pace. This fast-tracked development process means better-designed products can be introduced to the market sooner, which has implicit environmental benefits due to the faster adoption of more efficient technologies.

A testament to this transformative approach is Rolls Royce. As highlighted by Dr. Maksimovic, the company’s partnership with Ansys has yielded significant advancements in their engine design processes. By integrating Ansys software with Intel’s HPC libraries, Rolls Royce achieved a staggering 100-fold increase in their computational efficiency. What used to be a 1,000-hour process was reduced to just 10 hours.

This marked reduction in analysis time has unlocked the potential for more comprehensive design explorations, enabling aerospace companies to optimize their designs further than ever before and ultimately deliver products that are not only cutting-edge but environmentally conscious.

Ansys software also provides support for Airspace Link, part of Airbus’s connected cabin experience for commercial air travel. “Ansys SCADE provides a flexible and agile platform to enable Airbus to successfully implement new connected technology for future cabin configuration,” according to the company. SCADE is a model-based development environment that enables users to design and validate critical embedded software.